Sinto Molding Machine

SINTO Horizontal Flask-less Molding Machine manufactured by SintoKogio Ltd Japan

Model: FBO-IVN Flask size 711.2×660.4 (28”x26”)

Molding size: Cope 180-250 Drag 180-250 with 3 steps optionally set

Mold Rate: 100molds /hr

Squeeze surface pressure Max: 1.0MPa at 3 selectable stages

Power System: Air & Oil (30KW water cooled)

Air consumption: 2.5m3(N)/mold

Operating Air pressure: 0.5 to 0.55MPa

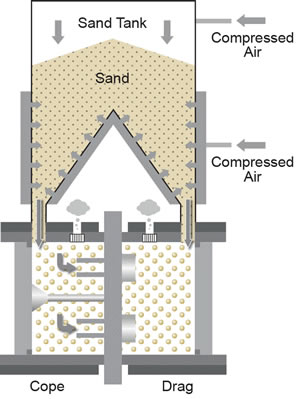

Aeration Sand filling makes mold difference, Low pressure air fluidises the sand to fill the complicated edges & Pockets in the pattern with sand Primary sand filling that is ideal for the production of molds with superior accuracy & uniformly high strength Achieves uniform sand filling density Uniform sand filling is realized without causing bridging at the complicated pattern profiles & throat of narrow pattern. Air consumption is reduced by as much as 70% compared to blow system. Low noise —75dB (A)

FBO-IVN molding machines is with simple mechanism with easy operations, Unique mechanism of blow pressure control realizes uniform sand filling density. Safe & operator friendly posture for core setting with drag mold shuttle mechanism. Pattern draw & pattern transferability are achieved by protecting distortion from unbalanced squeeze pressures. No distortion occurs even with existing thin match plates as well as those with large offset. FBO-IVN possesses superior pattern draw & highly accurate pattern transferability. Squeeze pressure is in balance control where pattern is well protected from adverse effect of offset load. The pressure difference between cope & drag during squeeze process is constantly monitored & automatically with the setup range of pressure difference. Increase in squeeze is automatically controlled during squeeze operation so as to avoid generation of unbalanced load to match plate. Reduces volume of molding sand & flexibly meet the variations of

compactability. Pattern changing time is less than 5 minutes.

Unique mechanism of blow pressure control realizes uniform sand filling density.

Aeration Sand Filling Technology

With Sinto’s aeration sand filling technology, low-pressure air fluidizes the green sand in the tank and fills the sand smoothly and uniformly into every cavity and corner of the pattern. This allows for primary sand filling that ensures high accuracy and uniformly high strength.

Production defects are reduced even with the production of complex shapes as a result of high-quality casting with superior dimensional accuracy, less weight dispersion, and no mismatching. This contributes to the long life and reliability of your products.