Facilities

Providing solutions of every kind, start to end

We have the following facilities in house to ensure that the manufactured patterns are defect free and of utmost quality.

Melting

Ductile iron treatment through sandwich process.

Pattern Shop

Pattern modelling and simulation with maintainance station.

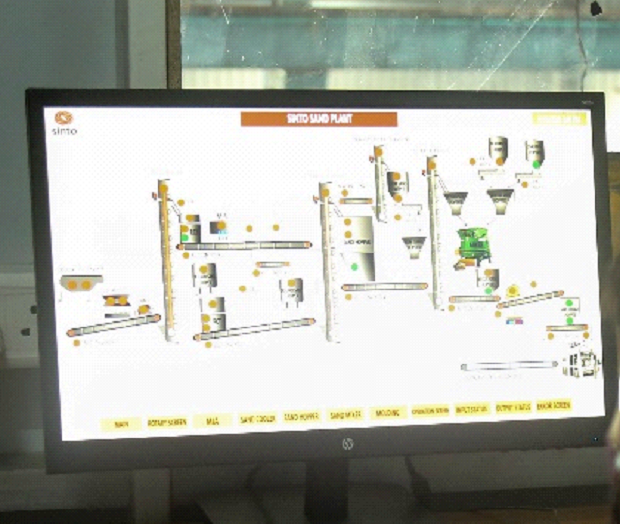

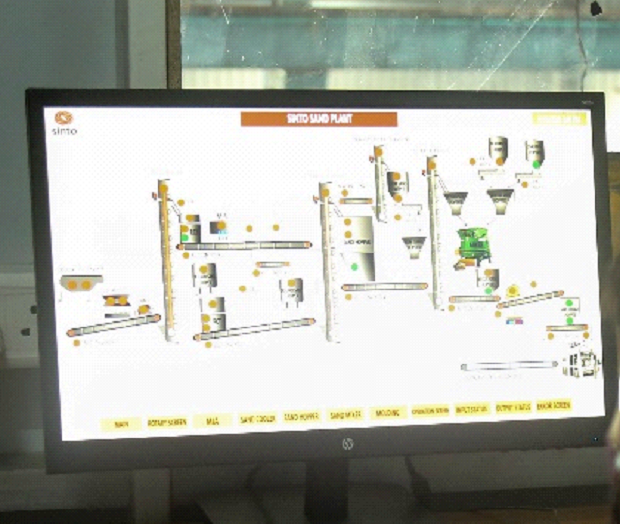

Sand Plant

40 tonnes per hour plant with SCADA to maintain control and monitor the input sand temperature and moisture.

Inspection

To ensure every manufactured pattern is of utmost quality. Spectrometer, Microscope, Brinell Hardness tester, CE meter, UTM machine, Height gauge and B4U cup with surface comparator.

1st Time approach

Process

The Difference

Between z-cast and traditional casting process.

The traditional process takes orders from the customer and creates casting designs. then experiments with various designs of patterns and puts them in production. If the model is not successful, the entire process is repeated. As opposed to this, the Z-cast process uses modern designing method to create 3d simulations as well as drawing of patters this is attained using the experience and the scientific knowledge collected by the experience of years of designing. The flow and solidification analysis of the designed patterns is checked. The Z-cast process improves the quality of produced patterns while reducing defects in them as well as increasing recovery incase defects are observed.

It is more time efficient and has no trial in making process. The yield is optimised and is of a higher quality. The overall process is high in efficiency and provides better results than the traditional process.

Know more about our facilities

Molding

SINTO Horizontal Flask-less Molding Machine

Model: FBO-IVN

Molding size: Cope 180-250 Drag 180-250 with 3 steps optionally set

Mold Rate: 100molds /hr

Squeeze surface pressure Max: 1.0MPa at 3 selectable stages

Power System: Air & Oil (30KW water cooled)

Air consumption: 2.5m3(N)/mold

Operating Air pressure: 0.5 to 0.55MPa

Develop

Pattern Design and Simulation

- 3D Modelling Software

(Solid Works). - AUTO CAST X 1

Simulation software - Pattern Making

Outsourced - Pattern Maintenance

Station. - Pattern Storage Racks

QA

Quality Inspection

Consistent evaluation & improvement in service

- Spectromax spectrometer

- Microscope

- Brinell Hardness tester

- CE meter

- Online sand testing equipment.

- UTM machine

- Incoming inspection material

facility. - Height gauge

- B4U cup

- Surface comparator

QC

Sand Plant

Model: RCT series

Gallery